A manual veneer press is one of the most important tools in a veneer shop. I built my veneer press over 25 years ago, and, although it was costly, it has become the backbone of the workshop, and has paid for itself a thousand times over the years. It is 54" wide inside the pipes and about 8" tall inside the clamps.

I usually keep several sheets of plywood as a bed, and heat large aluminum plates to press the veneer.

There are 10 units, each with 5 veneer screw clamps, and all of the units can be moved closer or farther apart to fit the work. I can press a full 4 X 8' marquetry sheet at once. For example, I used this press to make a marquetry table top which was 4 x 14' long.

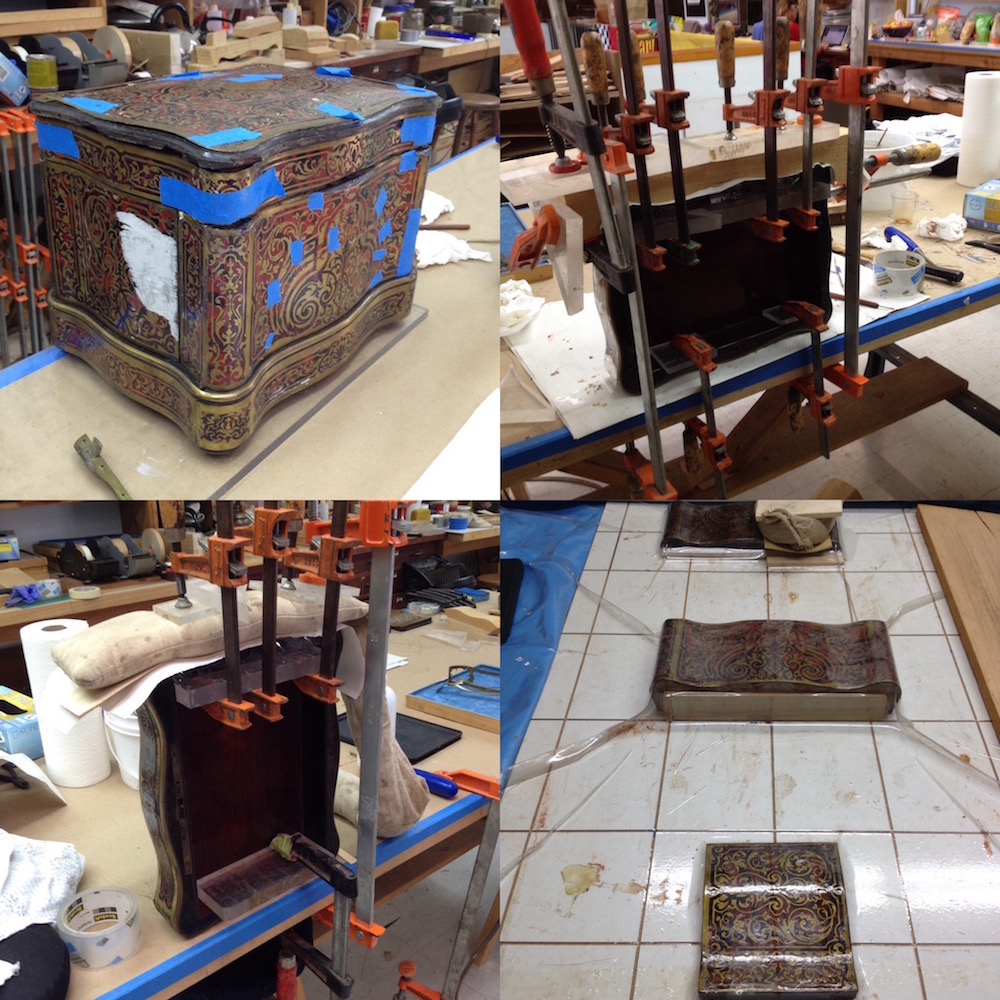

One the most common and interesting work in the shop is restoring early marquetry surfaces, which can either be repaired "in situ" or on the bench.

I recommend the use of sawn veneers when restoring pre-industrial furniture for their thickness. Sliced veneer, which appeared in the second half of the 19th century, is too thin.

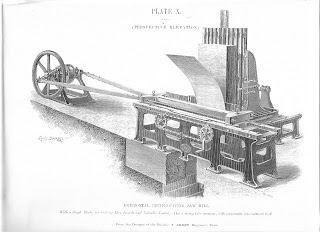

I get my sawn veneer from Patrick George in Paris, who operates a fourth generation veneer shop that has used the same horizontal saws since the start of the 19th century.